|

Art.680001.ZM1

one lever washbasin mixer, zinc chrome plated, with ceramic cartridge, with spout fitted with an aerator, with pop-up waste, with Aluminum wire flexible connection hoses (35cm long x 1/2" nut). |

|

Art.680002.ZM1

one lever washbasin mixer, zinc chrome plated, with ceramic cartridge, with spout fitted with an aerator, with pop-up waste, with Aluminum wire flexible connection hoses (35cm long x 1/2" nut). |

|

Art.680021.ZM2

one lever bath mixer, zinc chrome plated, with ceramic cartridge, with cast spout fitted with an aerator, with built-in diverter, with 1/2" connection for hose, wall mounted. |

|

Art.680011.ZM3

one lever shower mixer, zinc chrome plated, with ceramic cartridge, with 1/2" connection for hose, wall mounted. |

|

Art.680050.ZM5

one lever wall mounted sink mixer, zinc chrome plated, with ceramic cartridge, with movable high SS spout |

|

Art.680051.ZM4

one lever wall mounted sink mixer, zinc chrome plated, with ceramic cartridge, with movable SS spout |

|

Art.680032.ZM6

one lever sink mounted sink mixer, zinc chrome plated, with ceramic cartridge, with movable high SS spout |

|

Art.680001.ZN1

one lever washbasin mixer, zinc chrome plated, with ceramic cartridge, with spout fitted with an aerator, with pop-up waste, with Aluminum wire flexible connection hoses (35cm long x 1/2" nut). |

|

Art.680021.ZN2

one lever bath mixer, zinc chrome plated, with ceramic cartridge, with cast spout fitted with an aerator, with built-in diverter, with 1/2" connection for hose, wall mounted. |

|

Art.680051.ZN4

one lever wall mounted sink mixer, zinc chrome plated, with ceramic cartridge, with movable SS spout |

|

Art.680032.ZN6

one lever sink mounted sink mixer, zinc chrome plated, with ceramic cartridge, with movable high SS spout |

|

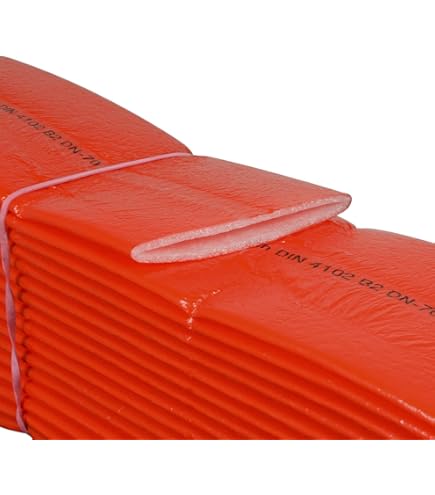

Art.13000xx Fleece Super Flex Insulation Tubes, 4mm thick, sound-absorbing tubular insulation with very strong and tough foil. Product Features: * Fleece hose made of 100% plastic fibers. Technical specifications: * Insulation thickness 4 mm |

|

|

Art.19000xx PE Super Flex Insulation Tubes, made of water resistant closed cell PE-foam 100% recyclable and (H)CFE free laminated with a strong foil, 4mm and/or 9mm thick, sound-absorbing tubular insulation. Product Applications: * For pipe protection against damages Technical specifications: * Insulation thickness 4 and/or 9 mm |

|

|

|

|

|

Differences in technical specifications and characteristics between the Fleece Insulation tubes and the new PE insulation tubes: |

||

|

Feature |

Fleece Super Flex Insulation Tubes |

PE Super Flex Insulation Tubes |

|

Material |

Foam core (or mineral/glass wool) wrapped in soft fleece |

Closed-cell polyethylene foam |

|

Outer Layer |

Soft, fibrous fleece |

Smooth PE skin; sometimes laminated with foil |

|

Flexibility |

Very flexible, easy to bend around curves |

Semi-rigid; slightly flexible but retains shape |

|

Thermal Performance |

λ ≈ 0.035–0.040 W/m·K; can be reduced if compressed |

λ ≈ 0.035–0.038 W/m·K; consistent over time |

|

Moisture Resistance |

Low; fleece can absorb water; needs separate vapor barrier |

High; closed-cell foam resists water and vapor; foil layer optional |

|

Durability |

Outer fleece can wear, fray, or tear |

Very durable; resistant to abrasion and mechanical damage |

|

Compression Resistance |

Can compress under pressure, reducing insulation efficiency |

Maintains shape; minimal compression |

|

Typical Applications |

Indoor plumbing, walls/ceilings, low-moisture environments |

Cold/hot water pipes, HVAC, industrial piping, outdoor use |

|

Pros |

- Soft and decorative |

- Excellent moisture resistance |

|

Cons |

- Less durable |

- Less flexible than fleece |

|

Art.680001.ZO1

one lever washbasin mixer, zinc chrome plated, with ceramic cartridge, with spout fitted with an aerator, with pop-up waste, with Aluminum wire flexible connection hoses (35cm long x 1/2" nut). |

|

Art.680021.ZO2

one lever bath mixer, zinc chrome plated, with ceramic cartridge, with cast spout fitted with an aerator, with built-in diverter, with 1/2" connection for hose, wall mounted. |

|

Art.680051.ZO4

one lever wall mounted sink mixer, zinc chrome plated, with ceramic cartridge, with movable SS spout |

|

Art.680031.ZO3

one lever sink mounted sink mixer, zinc chrome plated, with ceramic cartridge, with movable SS spout |

|

Art.680032.ZO5

one lever sink mounted sink mixer, zinc chrome plated, with ceramic cartridge, with movable high SS spout |

|

Art.831230 Pressure Gauge 25 bar / 350 psi in accordance with DIN EN 837-1 and KL1,6 Casing of 100mm ø, with ½” Brass Bottom Connection – Made in Germany Main functions of a pressure gauge in a piping system: Pressure testing: After the pipes and fittings are installed, the system is filled to a certain pressure, and the pressure gauge is used to measure and monitor this pressure. A drop in pressure indicates a leak that needs to be repaired. Operating pressure monitoring: During operation, the pressure gauge can be used to measure the current pressure in the system and ensure that it is within the permissible limits. Troubleshooting: An unexpected increase or decrease in pressure may indicate a problem in the system, such as a blocked pipe or a faulty valve. A pressure gauge can help diagnose and locate these problems. Safety monitoring: In industrial applications, a pressure gauge can be used to ensure that the operating pressure is within the permissible limits and that the system is safe. Leak detection: When installing pipes, a pressure gauge can be used to ensure that the connection has been made correctly and that no leaks are occurring. |

Page 23 of 24