|

Art.13000xx Fleece Super Flex Insulation Tubes, 4mm thick, sound-absorbing tubular insulation with very strong and tough foil. Product Features: * Fleece hose made of 100% plastic fibers. Technical specifications: * Insulation thickness 4 mm |

|

|

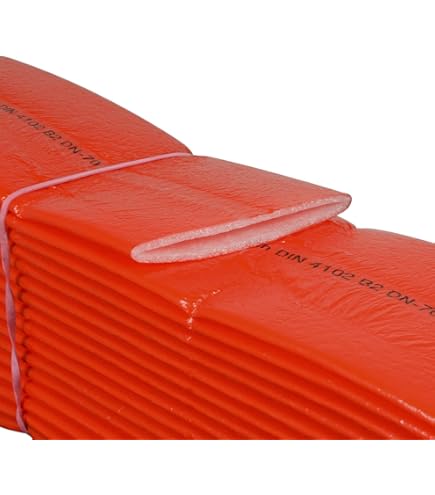

Art.19000xx PE Super Flex Insulation Tubes, made of water resistant closed cell PE-foam 100% recyclable and (H)CFE free laminated with a strong foil, 4mm and/or 9mm thick, sound-absorbing tubular insulation. Product Applications: * For pipe protection against damages Technical specifications: * Insulation thickness 4 and/or 9 mm |

|

|

|

|

|

Differences in technical specifications and characteristics between the Fleece Insulation tubes and the new PE insulation tubes: |

||

|

Feature |

Fleece Super Flex Insulation Tubes |

PE Super Flex Insulation Tubes |

|

Material |

Foam core (or mineral/glass wool) wrapped in soft fleece |

Closed-cell polyethylene foam |

|

Outer Layer |

Soft, fibrous fleece |

Smooth PE skin; sometimes laminated with foil |

|

Flexibility |

Very flexible, easy to bend around curves |

Semi-rigid; slightly flexible but retains shape |

|

Thermal Performance |

λ ≈ 0.035–0.040 W/m·K; can be reduced if compressed |

λ ≈ 0.035–0.038 W/m·K; consistent over time |

|

Moisture Resistance |

Low; fleece can absorb water; needs separate vapor barrier |

High; closed-cell foam resists water and vapor; foil layer optional |

|

Durability |

Outer fleece can wear, fray, or tear |

Very durable; resistant to abrasion and mechanical damage |

|

Compression Resistance |

Can compress under pressure, reducing insulation efficiency |

Maintains shape; minimal compression |

|

Typical Applications |

Indoor plumbing, walls/ceilings, low-moisture environments |

Cold/hot water pipes, HVAC, industrial piping, outdoor use |

|

Pros |

- Soft and decorative |

- Excellent moisture resistance |

|

Cons |

- Less durable |

- Less flexible than fleece |