* Standards & Norms

Our products comply with the following Germany & European Standards:

EN 200: Sanitary taps — General technical specification for single taps and mixer taps.

EN 246: Sanitary taps — General specification for flow rate Regulator.

EN 248: Sanitary taps — General technical specifications for Electro deposited nickel chrome Coatings.

EN 817: Sanitary taps — Mechanical mixers (PN10-General technical specifications (For single control mixing valve and other separate mixing valves).

EN 816: Sanitary taps — Thermostatic & Temporized taps.

EN 60742: Sanitary taps — Sensor taps.

EN 1113: Hand Shower Sets.

EN 3822-2: Bathroom Accessories, brass.

DIN 52218 & EN ISO 3822-2: Sanitary taps — General technical specifications for single and 2-handle taps.

DIN 19545 & DIN EN 411: Traps and Wastes, brass.

EN 411 & DIN 1997 / 19545: Traps and Wastes, plastic.

EN 274 & CSA 22944B/87: Bath Wastes and Over-flows.

DIN 1389 & DIN 1380: WC Trap-Connections, drainers.

DIN 18024 & DIN 18025: concealed cisterns.

EN 13828: ball valves, strainers.

DIN 2999: brass fittings.

* Quality Specifications

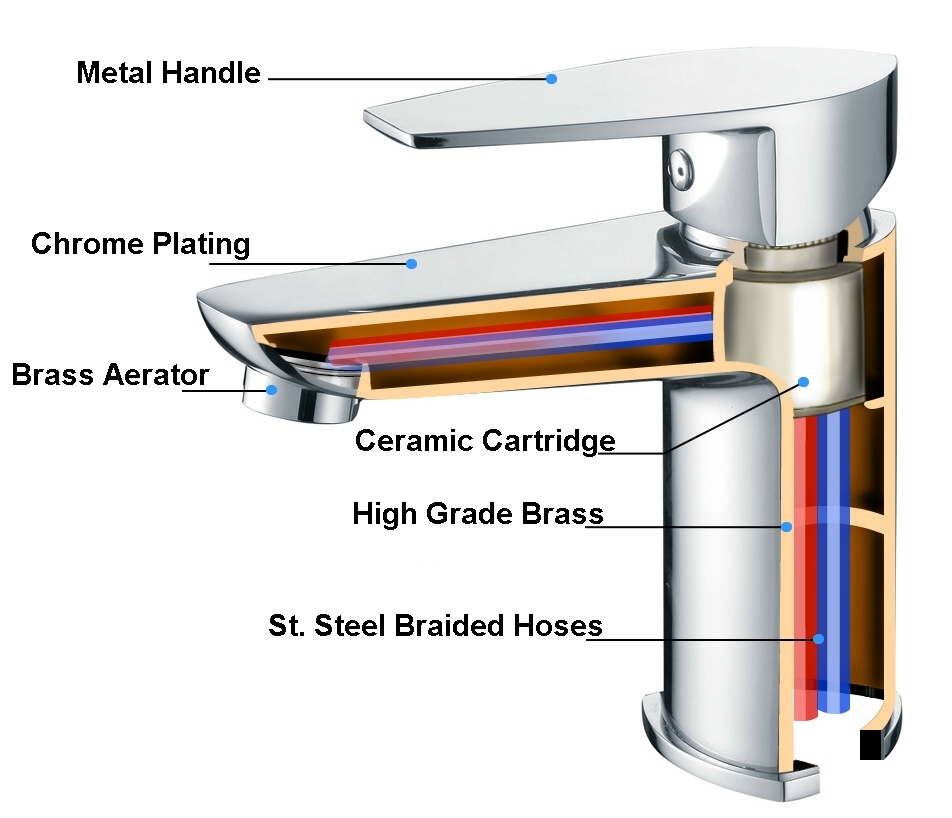

The product range of our company includes a wide selection of sanitary faucets as well as the accompanying sanitary equipment, the production process of which pays

maximum attention to quality and continuous improvement of the output.

'almanit' follows a strict selection of materials and components from the best global manufacturers, control of their chemical composition, physical parameters and production technologies in order to fully comply with the quality standards. It also includes a 100% verification of manufactured products before they reach the hands of

the buyer.

The technical and quality requirements of our faucet products are summarized as per the followings:

1. The thickness of electroplate:

- Nickel plate can be optionally supplied in the versions: 3-4um (standard), or 6-8um, or 10-12um

- Chrome plate can be optionally suppied in the versions: 0,15um (standard) or 0,25um

2. Coating quality:

2.1 Corrosion resistance testing-Neutral Salt Spray Test (NSS test) is 200 hours. Upon completion of the salt spray test, apparent surfaces shall not show any defect.

2.2 Coating adherence test-sectioning test: After testing has been carried out at three different places, there shall be neither peeling nor separation for coating.

3. The cartridges (head-part) used for our one lever faucets are of precise functioning with highest reliability with ceramic discs and a noise level 'B', which does not exceed 25db, in accordance with European regulations and ACS certification standards. The cartridges are designed to withstand frequent use of at least 70.000 cycles for opening and closing. By request, ceramic cartridges from SEDAL, or thermostatic cartridges from Vernet can be used.

4. The minimum flow pressure to activate the diverter function in our bath/shower mixer is 0.05Mpa (0.5bar) which is comply to European and international Standard.

5. Our faucets specification:

- Test pressure: 1.2Mpa (12bar)

- Flow pressure: Min. 0.05Mpa (0.5bar) - Max. 1.0Mpa (10bar)

- Recommended pressure: 0.1Mpa to 0.4Mpa (1 to 4 bar)

- Temperature at hot water inlet: Max.90°C

6. 'almanit' faucets are made from cast brass BS59. The lead composition of our brass is not exceeding 1.6% which complies to German and European standard. Brass, as a material, has antibacterial characteristics, thereby it improves the quality of drinking water.

7. 'almanit' faucets are available in a wide range of colors and color combinations:

| Chrome Plated | Black / Chrome | Matt Black | Black / Rose Gold | Brushed Gold | Rose Gold |

|

|

|

|

|

|

|

GREEN

We committed to the use of environmental protection and energy saving technology in the production of our products. We widely adopted the use of new materials and new technologies in the field of sanitary fittings manufacturing.

|

|

NOISE-FREE

The internal structure is precise, which is consistent with the principles of fluid mechanics, the precision internal structure and the design has ensured the silent and meticulous.

|

|

INNOVATION

Several ofappearance and utility model patents and invention patents, which have made outstanding contribution for the technology innovation of sanitary fittings and the developrnent of home furnishing culture.

|

|

SMOOTH

The unique Valve core is made from an advanced ceramic alloy in the dosed environment coated with special lubricating. The special storage tank design can ensure that the product is smooth for use as new for years.

|

|

BRIGHT

The Five-layer electroplating creates extremely deep and uniform coatings, and meanwhile the molecular structures between the coatings of copper, nickel and chrome plating are very dense, which makes it bright as a mirror, shining, dustproof, antifouling and able to resist scratches and never fade.

|

|

CONSTANT FLOW

Basin and kitchen faucet all has constant flowing bubbler which has overcome the traditional bubbler's disadvantages of larger pressure and lager flow. When the water pressure is above 0.14 Mpa, it has constant water flow which saves over 30% of water resou aces.

|

* WATER SAVING

All the day water is being used inside our homes in considerable quantities. It's estimated that over 70% of indoor water use takes place in the bathroom (example: when using the basin faucet, the shower faucet, the bidet faucet, the toilet … etc.). The bathroom is the main area for our water use and overuse. Thus, if we intend to save water consumption, the bathroom is the place to start with.

Reducing the water consumption means also reducing the energy required to heat it, so obtaining a reduction of CO2 emissions.

By using eco-friendly water-saving customized products with water and energy saving accessories, we can help to protect the environment and the climate. At the same time maintain having quality products that secures end-user with a top performance.

Eco-Stop Cartridges

Using a bathroom / kitchen faucet with an Eco-Stop ceramic cartridge can reduce about 50% of the water and energy consumption without compromising the end-user's needs and expectations.

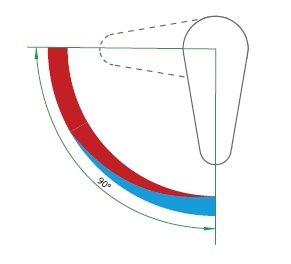

When using a standard cartridge and due to aesthetic and symmetrical reasons, the lever of the mixer is normally left in the central position and then opened and closed in such position where we would have warm water (between the hot and cold). But when using an Eco-Stop cartridge, the relationship between the position of the lever and the water temperature is such that, when the lever is in the central position, the water comes out cold. When the lever is turned to the left, the water becomes hot. The fact that the cold water flow starts at the central position helps to save both water and energy.

There are two brake mechanisms built into an Eco-Stop cartridge. These brakes are activated respectively once the temperature reaches 38°C, and the flow capacity reaches 9 l/min.

- When turning the faucet lever to the left, the user will feel some resistance at a certain point. This is the point at which the water temperature has hit approximately 38°C.

- When a faucet with an Eco-Stop cartridge is opened, an automatic brake applies itself at the point at which the water capacity reaches 9 l/min. This flow is normally enough to satisfy any day-to-day need, but should the user find capacity too low, they can simply overcome the brake to increase the flow. This prevents the user getting too much water when it is not required and therefore saves on water usage.

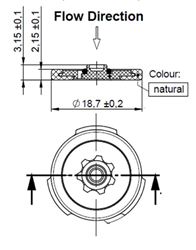

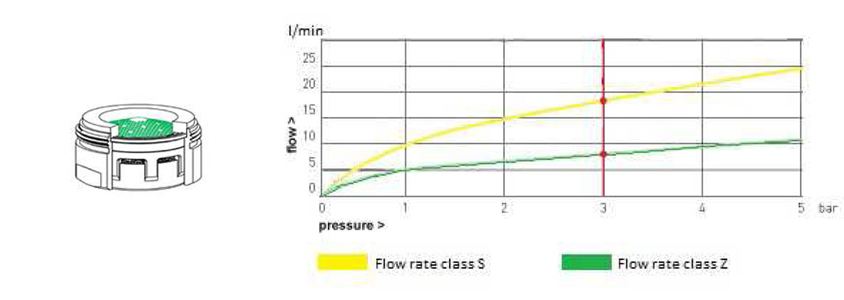

Flow Regulating Aerators

Flow regulators are used in faucets, kitchen sprays, showerheads and shower hand sprays to meet flow requirements and to help save water and energy without sacrificing comfort of use. By diluting the water stream with air, aerators significantly reduce the volume of water flowing from the faucet. They do this while maintaining the feeling of a high-pressure flow. The intensity of the water jet is the same: only the quantity of water changes because of the addition of air.

The low water flow aerator has a 7,5 l/min flow at a 3 bar pressure. It belongs to class Z. The common aerators have a flow of about 17 l/min at a 3 bar pressure and they belong to class S.

For the bathroom taps, wash basin and bidet faucets, and for the kitchen taps we can supply our products with an aerator giving the flow rate of 6 l/min which is in accordance with most standards. Lower values can be reached when requested. Please contact us for more details.

Flow Regulating Washers

the shower heads, hand showers and connection hoses could be supplied with Flow Regulating Washers allowing a MAX flow rate of about 8 l/min which is in accordance with most standards.